The VALENTINI cable yarders’ drums are well visible but nevertheless well protected, since when the unloading point’s conditions are particularly difficult some log can get a bit closer to the machine.

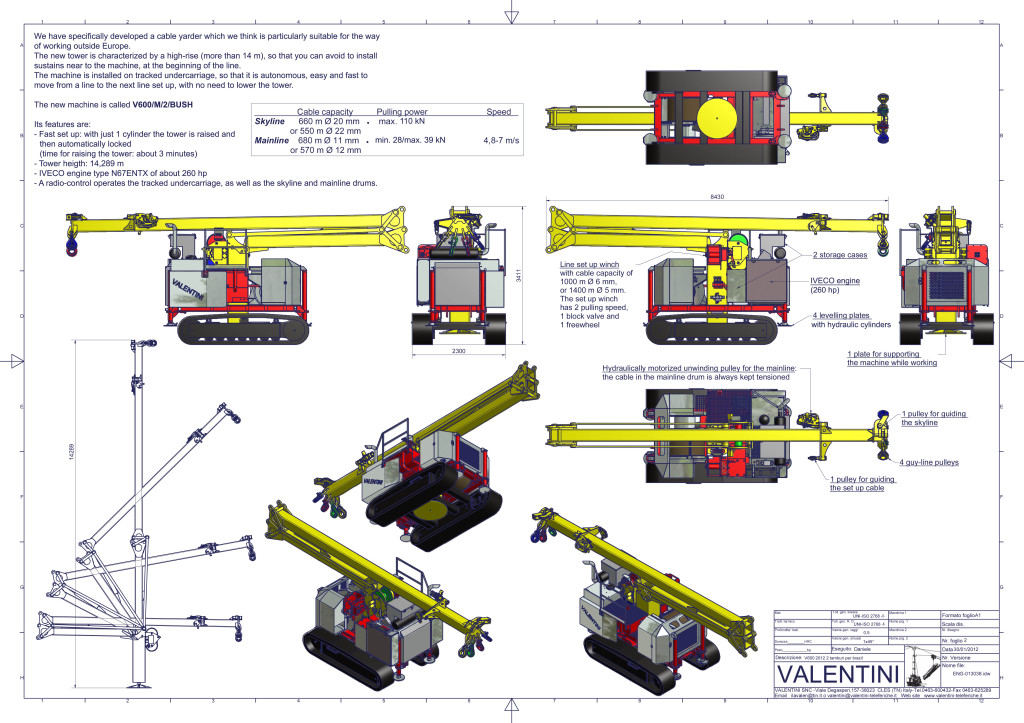

On most new models it is not necessary to install a cable guide device for the mainline: the tower is simply equipped with a cable unwinding pulley, which allows to optimise the mainline cable’s tension during its winding and unwinding on the drum. In this way there are no cable slacks and additional safety is provided.

All the models have a radio-controlled safety lowering function for the skyline in case of emergency. In event of skyline overloading the drum’s brake slips in a controlled way, in order to reduce the cable tension and to respect in this way the cable’s safety parameters.

Our machines offer wide possibilities of fine-tuning the automatic path control system, according to the specific harvesting conditions: this allows to work in a more efficient and safer way. Furthermore, an automatic unloading function is being developed.

Cable yarders on tracked undercarriage have major advantages regarding compactness and manoeuvrability. There is no cab and the whole machine is all-round protected, as forestry machinery should always be.

Such a machine can climb for reaching areas that would be unapproachable for a trailer or a truck. These cable yarders are completely radio-controlled, also for the driving functions: in this way no-one will have to be in the danger area while the machine is moving.

Tracked cable yarders can be placed on any ground good enough for bearing the machine’s weight.

For wintertime the tracks can be equipped with special removable ice studs plates, which ensure good grip on ice and snow.